|

An endvise is a beautiful thing to

use

No woodworker should ever have to try

and live without one. You want something massive, immoveable and outright

secure. Attractiveness isn't much of a penalty either.

Traditionally these were made of all wood. Very beautiful but somewhat fragile I

thought. Also a long detailed project. I wanted one I could hop right up and

plop my butt on without the slightest concern. Rough and tumble but looking like

a traditional vise from the outside.

Hardware

kits are available. Pretty spendy though and the screw is around an inch

diameter at best. The commercial iron vise slides mainly consist of long

slots milled into steel plates and a flat plate the thickness of the slot width.

Effective, but there isn't any way to compensate for wear. Also cost around 100

bucks. I don't have a milling machine so copying this was unlikely.

Mine is built around the taper present on the inside legs of angle iron. Common

angle iron has a taper around 2 to 4 degrees on each leg. This make a natural

"draw" to slide down. Kind of like a big dovetail.

So what I did was cut off most of one leg of 2 pieces of 1 1/2" angle, each

around 10" long, leaving the other long to attach to my wood parts. Since it's

the inside corner of the angle iron that slides you don't need to cut the angle

leg off accurate. Just lop if off leaving a short leg around 1/2" long.

By slicing 3 pieces of 1/2" common water pipe at precise lengths with squared

off ends, I could not only use them as spacers to hold the legs, but in the

event of wear all I have to do is take them back off and shorten them just a

bit. The inner diameter of 1/2" water pipe actually passes a 5/8" bolt just

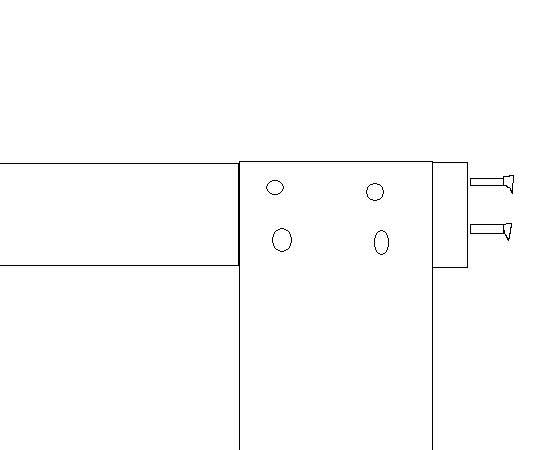

about perfect. The shot shows the end of this assembled sliding jaw.

http://users.snowcrest.net/kitty/scott/bench3x.jpg

That's the top angle, and the first of the water pipe spacers plus the big

screw in the middle. See the bolt going through the angle and the spacer??

Plastered to the side of the bench with long lag bolts, I used 2 layers of

1/4" steel plate. One wider set on top for the short legs of my slide to grab

and the other narrower for clearance and to furr out the height of it. The nut

is welded to the outermost plate.

All in it cost me $5 for the screw and nut, and I had to buy some 5/8" nuts

since I didn't have enough. The rest was strictly boneyard scrap all the way.

Stuff you can find at any scrap pile or dump in the world. None of it is going

to show at the end so any old rusty junk that isn't bent will do you fine.

--These are ballpark memory measurements-- You'd have to figure everything out

to fit your own bench, same way I did.

3 bolts, 5/8" X 6" long with nuts to match.

2 pieces of 10" X 1 1/2" angle.

3 pieces of 1/2" water pipe, ± 5" long

1 piece of 1/4" X 5" wide plate X around 12-14" long, ordinary mild plate steel.

(you futz around getting the long sides parallel)

1 piece 1/4" X 4" X 12-14"long plate (this one is fine in rough cut form, it's

just a spacer)

6, 6" long lagbolts, 1/2" diameter, to nail the plates to the side of the

bench

It started for me when I had the chance to

buy an old apple press screw at a yard sale. This is a massive screw. About

1 1/2" diameter and a fast square thread on it.

This pic below shows you the backside or inside with the bolts/spacers holding

the angle apart. You can see one leg of the angle is sawed short.

|